Out with the old, in with the new – Aquaseal’s new machinery set to increase productivity levels in the workshop

10th September, 2019

Aquaseal’s latest machinery arrived in the office last week, and we’ve already put it to work! We’ve replaced our old machinery with a shiny new DCR BP60T beam press and brand new GSB-20T swing press, manufactured by DCR Machines.

Both of our new presses are used for cutting out components of various sizes, materials and thickness. They’re able to do this with more speed and efficiency than the old travelling head press and swing beam press we have used for some 15 years, meaning we’re able to increase our overall productivity in the office. In turn, this helps the customer with quicker lead times.

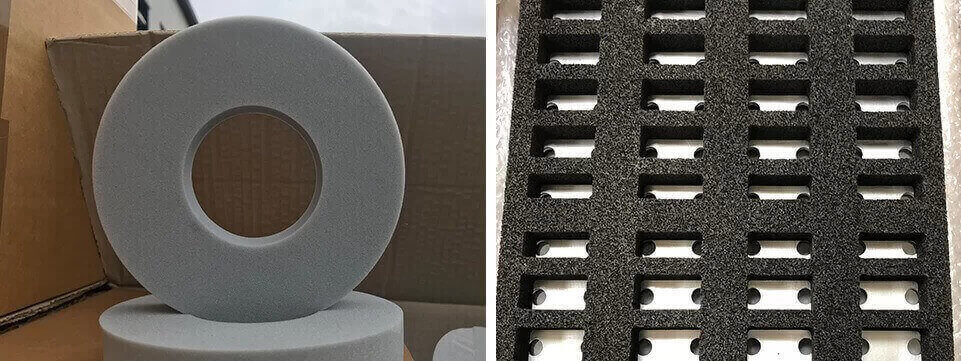

The range of thickness that the new press can cut ranges from less than 1mm thick up to 25mm of thick solid rubber. The types of materials we can cut on the machines include solid rubber, sponge, foam, fibre and flexible materials like polyurethane, PVC and many other plastics and allied materials. This is ideal for our diverse client base and bespoke rubber service.

We’ve already put the new swing press and refurbished beam press to the test, creating rubber and plastic products in a range of shapes and sizes as you can see in the pictures.

Want to find out how Aquaseal can help your project? Get in touch with us today.