Polyurethane roller covering

12th December, 2017

Enquiry

The initial enquiry was an email from the customer who is based in the UK, looking for roller covering. After a series of phone calls to cover specifications, drawings were issued so that we could do the pricing. And once pricing was approved, an order was placed from the head office, located in The Netherlands.

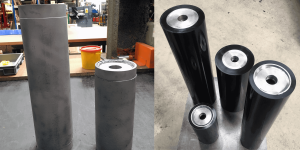

The order was for a complete supply of steel rollers covered in 90 shore polyurethane. So we started on the fulfillment.

Delivery

We knew that the physical size of the rollers, along with the weight of steel would be the biggest challenge on this project. The weight also increased with the application of the polyurethane coatings, manoeuvring the rollers while applying the coatings become more difficult over time.

The grade of steel had already been specified by the customer in the initial enquiry and was handled by an external partner, so we were able to advise on what material would be best. We went with polyurethane because of the harsh conditions the rollers would continually be exposed to. It also offered protection against ozone and weather degradation so that the coverings will continue to stand the test of time and environment.

The 90 shore polyurethane can handle any condition out at sea, on any type of sea faring vessel.

Results

The customer was happy with the final product and our customer service process, which makes the project a success in our eyes.

Production operator Tony had this to say of the project “ It was good to see a nice volume of coating go through the works and the items looked great once we had carried out all out coating procedures. The steel company did a good job with the finish of the rollers which made our job easier.”

If you’re looking for coverings for your off shore equipment or have a project in the off shore industry that Aquaseal Rubber could help with, get in touch!