Polyurethane

Shore hardnesses can be softer than a pencil rubber, harder than nylon or anywhere between.

Aquaseal Rubber Ltd manufactures the following polyurethane products:

- Shocks

- Isolators

- Seals

- Impellers

- Gaskets

- Pinch Rollers

- Capper Rings

- Bushings

- Cams

- Metal Forming Pads

- Cutting Surfaces

- Mounts

- Bumpers

- Bearings

- Blocks

- Elastomers

- Coverings

- Dies

- Gears

- Linings

- Springs

- Straps

- Tubing

- Washers

- Wheels

- Flexible Couplings

- Casters

- Plugs

- Sheets

- Scrapers

- Pads

- Absorbers

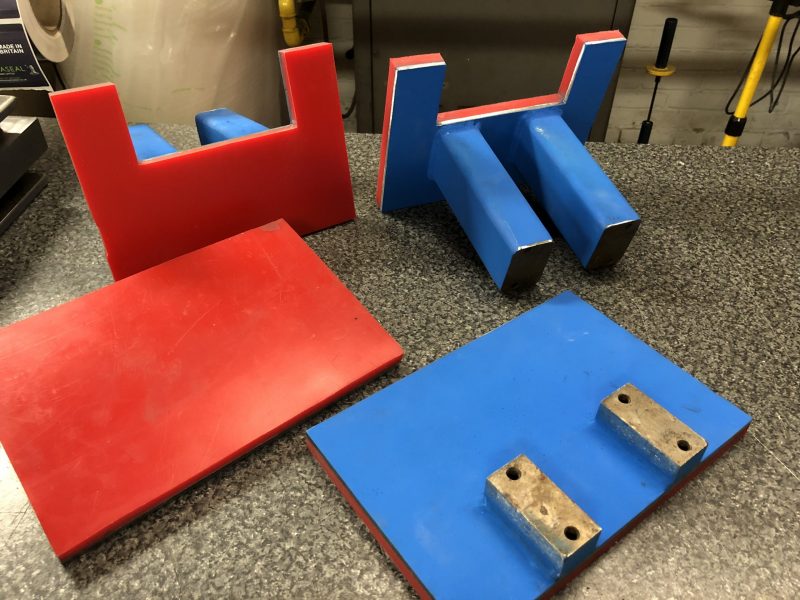

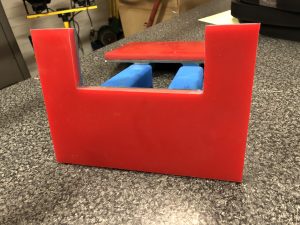

CUSTOM OPEN-CAST GOODS

Open-cast urethane and polyurethane moulding produce a wide variety of products for most industries.

Urethane surpasses most other polymers for applications requiring:

- high abrasion resistance

- outstanding tensile and tear strength

- noise dampening

- chemical resistance

- excellent load-bearing capability

Urethane can replace expensive metal casting. It is lightweight and still maintains or exceed wear characteristics found in their metal counterparts. We can make polyurethanes to maximise particular specifications. This includes maximising abrasion, and increasing tensile strength to get a strong, break-resistant part.

The ingredients in some urethanes are FDA approved for contact with foodstuffs. This means they can be used in food services and production as well as the medical industry.

URETHANE ROUND BARS

We offer many sizes of Round Bar, ready to ship within a few days. These are at competitive prices and in a wide range of durometers. Our standard pricing covers durometers from 50-100 on the “A” scale and up to 60 on the “D” scale. We have special pricing for softer and harder urethanes. Please see the price list or call us for pricing on hardness and sizes not listed.

SHEETING

Sheeting can be produced in a variety of dimensions. There are many methods used including centrifuged, flat cast, moulded and extruded.

Applications include:

- cutting or punching gaskets

- scrapers and flaps

- protecting industrial table tops

- lining wear chutes

- blast cabinets

HOW WE DO IT:

- Polyurethane, dispensed in liquid form into heated moulds, from modern dispensing machines

- After heat curing, parts are trimmed or machined finish

- This process produces the most durable urethanes

- Mould costs will generally be comparatively low

- Widest shore hardness range (10°A to 95°D)

- Natural (translucent) or pigmented components in a wide range or colours (to RAL specification if required)

- Process suits high or low volume production